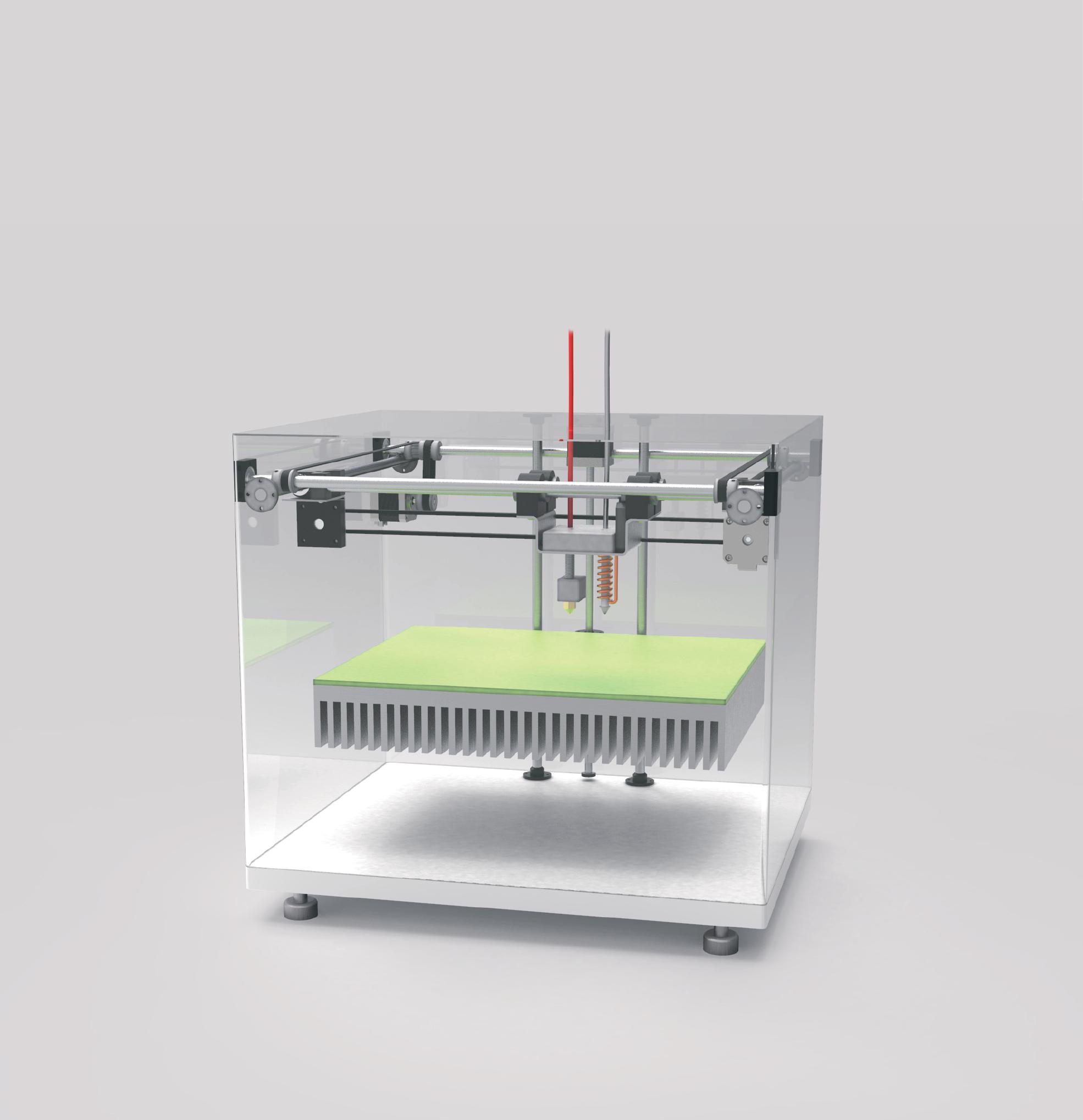

Reduced cost of printing

Additive manufacturing has a shorter lead time than conevntional techniques such as milling or casting. It uses just the amount of material, thus, decreasing the waste production. Moreover, our technique eliminates powder use (no powder removal or debinding). Only basic safety measurements are required such that operational costs are reduced significantly.